Laserschneiden Bleche: Benefits & Applications

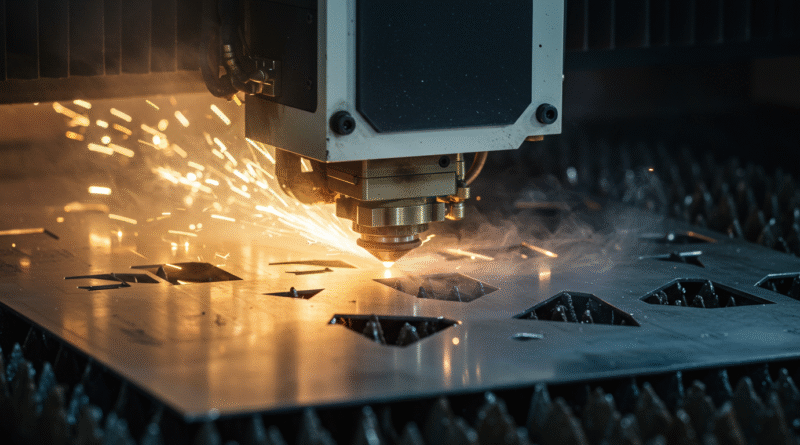

laserschneiden blecheWhy Laserschneiden Bleche Is a Big Deal Right Now

Ever tried cutting sheet metal with a manual saw? It’s like using a butter knife to slice steel—messy, slow, and frustrating. That’s where laserschneiden bleche (laser cutting sheet metal) comes in and changes the game.

Whether you’re in manufacturing, construction, automotive, or just love DIY metal projects, laser cutting offers pinpoint precision, speed, and versatility. Think of it as the “lightsaber” of metalwork—clean cuts, minimal waste, and incredible accuracy.

In this guide, we’ll dive deep into the top benefits of laser cutting metal sheets and explore real-world applications that prove it’s not just hype—it’s the future of fabrication.

Top Benefits of Laserschneiden Bleche

So, what makes laserschneiden bleche such a powerful method? It’s not just about cutting—it’s about cutting better, faster, and cleaner. Here’s what you gain:

| Benefit | Why It Matters |

|---|---|

| Extreme Precision | Clean, accurate cuts—ideal for detailed or complex shapes |

| Fast Processing | Cuts down production time, perfect for high-volume jobs |

| Smooth Edges | No rough burrs or extra sanding required |

| Low Thermal Impact | Less heat distortion = better quality on delicate materials |

| Wide Material Support | Works on steel, aluminum, stainless, copper, and even titanium |

Laser cutting is like the difference between drawing with a crayon and a fine-tip pen—it’s that exact. When every millimeter counts, you want a tool that delivers laser-sharp results (pun intended).

Where Laserschneiden Bleche Is Used

You might be wondering: “Where exactly is all this laser magic happening?” Well, just about everywhere. Here’s how different industries are embracing laserschneiden bleche:

1. Automotive & Aerospace

From chassis components to exhaust systems, the auto and aerospace industries rely on laser-cut sheet metal for strength and accuracy.

2. Architecture & Interior Design

Ever seen a beautifully patterned metal railing or custom metal ceiling tiles? Those are often laser cut for precision and beauty.

3. Manufacturing & Machinery

Machine parts, enclosures, brackets, and fittings—laser cutting keeps things tight, consistent, and repeatable in industrial settings.

4. Art, Furniture, and Decor

Designers and artists use laser cutting for personalized signs, furniture elements, metal wall art, and more.

Which Materials Can Be Laser Cut?

Laser cutting isn’t a one-size-fits-all process—it’s super versatile across materials. Here’s a helpful breakdown:

| Material | Laser Cutting Suitability | Special Notes |

|---|---|---|

| Mild Steel | ✅ Excellent | Cost-effective and commonly used |

| Stainless Steel | ✅ Excellent | Great for food-grade and decorative projects |

| Aluminum | ✅ Very Good | Reflective—needs specialized equipment |

| Copper & Brass | ⚠️ Limited | Highly reflective, needs fiber lasers |

| Titanium | ✅ Excellent | Often used in aerospace and medical fields |

FAQs About Laserschneiden Bleche

1. What does laserschneiden bleche actually mean?

It’s German for “laser cutting sheet metal.” It refers to using lasers to cut flat metal sheets into desired shapes with precision.

2. Is laser cutting more expensive than other methods?

It can be slightly more costly upfront, but it’s faster, more accurate, and cleaner—saving money on finishing and waste.

3. Can I use laser cutting for one-off custom parts?

Absolutely! Many shops accept single-item jobs, especially for prototypes, artwork, or repair parts.

4. How thick can the metal be for laser cutting?

Typically, lasers cut metal sheets from 0.5 mm to 25 mm thick, depending on the power and material type.

5. Where can I get laser cutting services?

Plenty of manufacturers and online services offer laserschneiden bleche options—just upload your design file and go!

Conclusion: Why Laser Cutting Is the Smart Choice for Sheet Metal

To sum it all up: laserschneiden bleche isn’t just another metalworking trend. It’s a revolution in how we approach cutting, shaping, and designing with metal. Whether you’re looking for speed, flawless accuracy, or a way to turn a creative vision into reality—laser cutting has your back.

So next time you need to cut metal, ask yourself: do I want rough edges and headaches… or laser precision?

⚙️ Looking to level up your next project? With this guide to Laserschneiden Bleche: Benefits & Applications, you’ve got the know-how to cut with confidence.